They are “industrial” because they are designed for use in manufacturing facilities, construction zones, and other high demand areas. These vacuum cleaners are high-powered machines capable of collecting much more material with greater efficiency than commercial vacuum cleaners. Read More…

As a leader in the vacuum cleaner manufacturing industry, Multi-Vac offers vacuums for a variety of applications. Products include central industrial vacuums, portable vacuum cleaners and more.

Delfin Industrial Vacuums is an innovative leader in the vacuum cleaners industry. We focus on continually improving our products and our services, so you are only ever getting the best from us. Our team is dedicated to finding the right industrial vacuum system for your company’s specific needs. Delfin is an ISO 9001 certified company. We offer our customers unrivaled customer service and...

We aim to achieve measurable cost savings for you while producing a cleaner and safer work environment in your workplace. We meet your needs for cleaning or maintaining, recycling, non-destructively excavating, or improving air quality.

At Mark C. Pope Associates, we take pride in offering advanced vacuum cleaning solutions tailored to meet the rigorous demands of industrial and commercial environments. With decades of experience in the field, we have built a reputation for delivering high-performance vacuum systems that stand up to heavy-duty use while ensuring efficiency, safety, and cleanliness in every application.

More Industrial Vacuum Cleaner Manufacturers

Industrial Vacuum Cleaners: Comprehensive Guide, Applications, and Buying Considerations

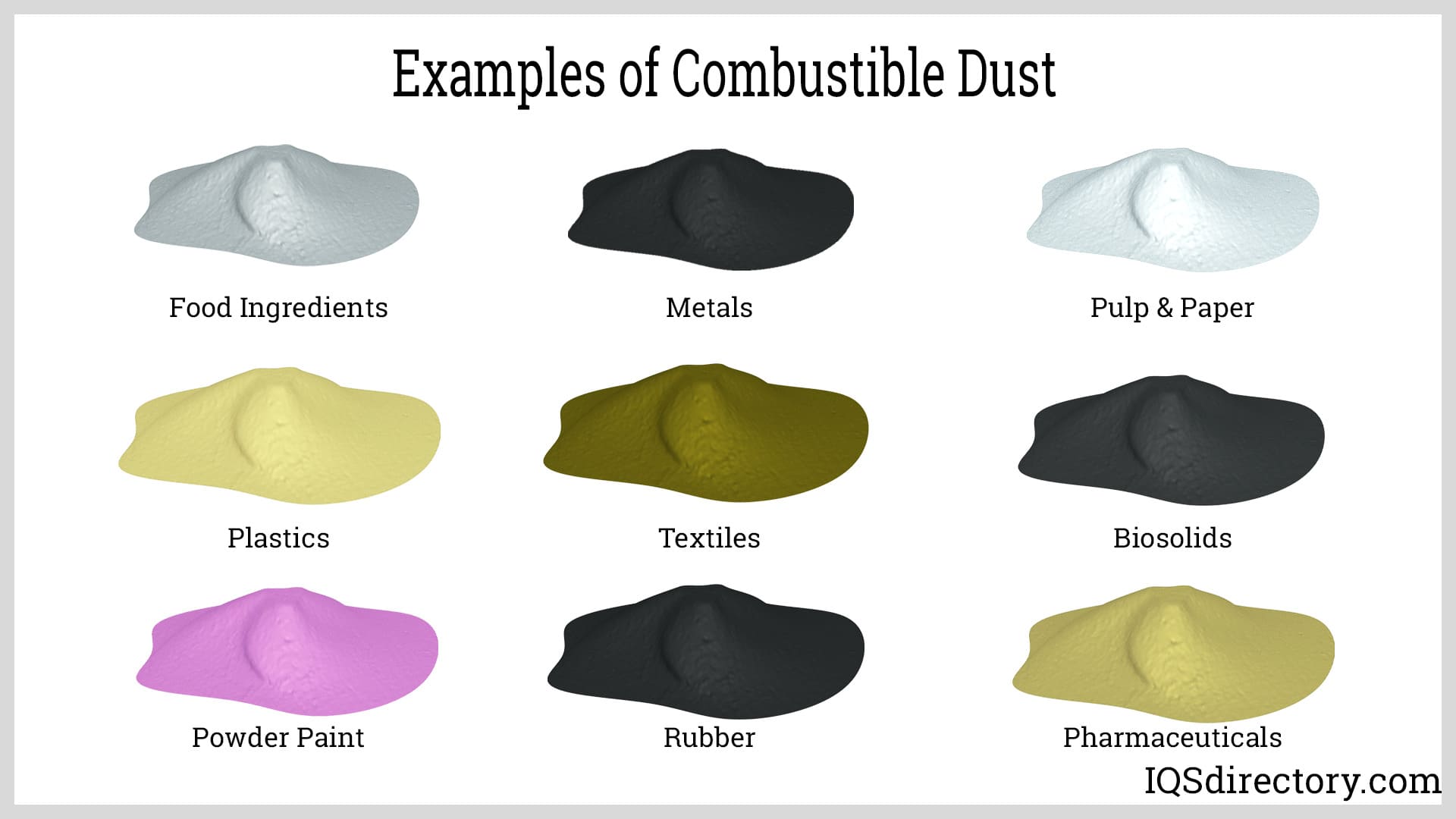

Industrial vacuum cleaners are essential equipment in today’s manufacturing, commercial, and production environments, playing a critical role in facility maintenance, environmental health, and operational efficiency. These high-performance, professional-grade vacuum systems are specifically engineered for industrial cleaning tasks in manufacturing facilities, warehouses, food processing plants, pharmaceutical sites, construction areas, and a wide variety of other industrial settings. Unlike standard household vacuums or light-duty commercial vacuum cleaners, industrial vacuum cleaners are designed to handle demanding jobs, removing a broad spectrum of challenging materials such as fine powders, abrasive dust, explosive media, litter, non-free flowing substances, metalworking chips, coolants, oil mist, toxic dust, and welding fumes.

Beyond general cleaning, these heavy-duty vacuum systems are indispensable for material reclamation, recycling operations, and efficient spill recovery. Industrial vacuum cleaners support compliance with workplace safety regulations, such as OSHA, EPA, and NFPA standards, by maintaining a clean, safe, and productive environment. Whether you’re seeking an industrial dust collector, a hazardous material vacuum, or a HEPA-filtered vacuum for fine particulate control, understanding the right solution for your facility is crucial to maximizing value and operational uptime.

What Are Industrial Vacuum Cleaners?

Industrial vacuum cleaners are robust, high-capacity cleaning systems built to withstand the rigors of continuous operation in demanding, large-scale industrial environments. Their powerful motors, advanced multi-stage filtration systems, and rugged construction enable these machines to collect hazardous dust, bulky debris, fine particulate matter, and even liquids—tasks far beyond the reach of most standard commercial or residential vacuum cleaners. These machines are an integral part of facility maintenance programs, production line cleaning, environmental health and safety (EHS) compliance, and industry-specific hygiene protocols.

Industrial vacuums range from portable units for spot cleaning to centralized vacuum systems capable of servicing entire buildings. With specialized attachments, variable suction control, and customizable filtration, these systems provide targeted solutions for virtually any industrial cleaning challenge. Their versatility also extends to specialized roles such as combustible dust collection, hazardous waste recovery, and process-integrated vacuuming in cleanrooms and controlled manufacturing environments.

Key Applications of Industrial Vacuum Cleaners

Industrial vacuum cleaners serve a diverse range of industries and applications, addressing the unique cleaning, safety, and compliance needs of each sector. Understanding the most common and critical uses can help you identify the right type of industrial vacuum system for your facility’s requirements:

- Manufacturing Facilities: Remove dust, metal chips, abrasive powders, shavings, and other production byproducts from machinery, assembly lines, and equipment to maintain product quality, minimize equipment failure, and support lean manufacturing initiatives.

- Metalworking: Collect metal chips, swarf, sharp shavings, and coolant in machine shops and fabrication facilities, ensuring a safer workspace while preventing product contamination and reducing wear on cutting tools and machinery.

- Woodworking: Extract sawdust, wood chips, and fine particulate matter from cutting, sanding, and finishing operations, reducing fire hazards and improving air quality for worker health.

- Automotive Industry: Clean up oil spills, metal fragments, abrasive dust, and paint overspray on assembly lines, shop floors, and in vehicle service departments.

- Food Processing: Remove food particles, dust, allergens, and spilled ingredients to meet stringent hygiene standards, pass audits, and avoid costly recalls.

- Pharmaceutical Plants: Capture hazardous powders, allergens, and fine contaminants during blending, tableting, and packaging to ensure product purity and worker safety.

- Construction Sites: Eliminate construction debris, concrete dust, and hazardous silica during renovation, demolition, or new build projects, keeping sites safe and compliant with OSHA dust control standards.

- Spill Recovery: Quickly respond to hazardous spills—both liquid and powder—minimizing facility downtime, environmental impact, and regulatory risk.

- Recycling Operations: Reclaim valuable raw materials, separate waste streams, and reduce material disposal costs in recycling plants and waste management facilities.

- Cleanroom & Electronics Manufacturing: Maintain ultra-clean environments by collecting micro-particulates, soldering fumes, and static-sensitive debris.

If you’re looking for a vacuum system tailored to your industry, contact our specialists for a personalized equipment recommendation that meets your operational and regulatory requirements.

Types of Industrial Vacuum Cleaners

The right industrial vacuum solution depends on your facility’s specific cleaning requirements, materials handled, and environmental constraints. Here are some of the most common types and configurations of industrial vacuum cleaners, each designed for unique applications:

- Canister Vacuums: Versatile, highly portable units that are ideal for spot cleaning, routine maintenance, and reaching under machinery or into confined spaces. Common in workshops and maintenance departments.

- Walk-Behind or Rider Sweepers: Designed for efficient cleaning of large floor areas in warehouses, production plants, and distribution centers. Rider sweepers reduce operator fatigue and speed up cleaning cycles.

- Backpack Cleaners: Ergonomic, wearable vacuums that offer unmatched mobility for cleaning tight, elevated, or hard-to-reach areas such as catwalks, stairs, and facility rafters.

- Continuous Duty Vacuums: Heavy-duty vacuum systems built for round-the-clock operation in demanding environments such as production lines and process industries. These units feature large collection tanks and robust components for minimal downtime.

- Explosion-Proof Vacuums: ATEX-certified and intrinsically safe models designed specifically for combustible dust, flammable materials, or hazardous area cleaning. These vacuums feature anti-static hoses, conductive wheels, and spark-resistant construction.

- Vacuum Cleaner Trucks: Industrial vacuum trucks provide high-capacity, mobile suction for outdoor, municipal, or large-scale spill recovery projects such as catch basin cleaning, tank cleaning, and environmental remediation.

- HEPA Vacuum Cleaners: Equipped with certified HEPA filters to trap ultra-fine particles, toxic dust, and hazardous contaminants. Essential for industries requiring OSHA and EPA compliance, such as asbestos or lead abatement.

- Central Vacuum Cleaners: Permanent, stationary vacuum systems that use a network of ductwork or piping to provide comprehensive cleaning coverage across large buildings, production complexes, and multi-floor facilities.

- Auto Vacuums: Specially designed for automotive detailing, carwash operations, and vehicle service bays. These units offer powerful suction and specialized attachments for cleaning vehicle interiors, upholstery, and floor mats.

- Wet/Dry Industrial Vacuums: Dual-purpose vacuums designed to collect both dry debris and liquid spills, reducing the need for multiple machines and streamlining cleaning workflows.

- Portable Industrial Vacuums: Compact, maneuverable models that provide high suction power for spot-cleaning, machinery maintenance, and tool crib applications.

How Does an Industrial Vacuum Cleaner Work?

The operating principle behind industrial vacuum cleaners is the creation of a strong suction force, typically generated by a high-efficiency electric motor, regenerative blower, compressed air (for pneumatic models), or vacuum pump. This suction draws dust, debris, particles, or liquids through a flexible hose, where they pass through one or more filtration stages before being deposited in a collection tank or bag. Clean air is then exhausted back into the environment, while contaminants are safely contained.

Advanced industrial vacuums may feature multi-stage filtration—including cyclonic pre-separation, cartridge filters, and high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters—to capture a broad range of particle sizes, including hazardous or combustible dust. Some systems also include automatic filter shakers, sensor-based filter monitoring, and programmable cleaning cycles to maximize uptime and filtration efficiency. For liquid and slurry applications, wet vacuums use corrosion-resistant tanks, float shut-off valves, and specialized squeegee attachments.

Filtration Systems: Wet and Dry Industrial Vacuums

Choosing the right filtration system is critical for safe, effective, and compliant industrial cleaning. Leading manufacturers offer a range of filter configurations tailored to specific cleaning tasks and industry regulations:

- Dry Vacuum Filters: Engineered for dust, powders, sawdust, and dry debris. Common filter types include cartridge, bag, and cyclonic filters—ideal for woodworking, metal fabrication, and dry process industries.

- Wet Vacuum Filters: Designed for liquid pick-up, oil recovery, and environments with mixed debris streams. These systems often feature mesh or foam filters resistant to clogging and corrosion.

- Combination (Wet/Dry) Filters: Hybrid systems that handle both wet and dry materials, streamlining cleaning logistics and reducing equipment downtime for facilities with mixed waste streams.

- HEPA & ULPA Filters: Certified high-efficiency filters for critical environments, such as pharmaceutical manufacturing, food processing, electronics cleanrooms, and hazardous waste remediation. These filters capture 99.97% (HEPA) or 99.999% (ULPA) of fine particulates down to sub-micron sizes.

Still not sure which filtration system matches your cleaning requirements? Ask our experts for advice on selecting wet, dry, HEPA, or combination filtration for your industrial vacuum system.

Benefits of Using Industrial Vacuum Cleaners

Investing in an industrial vacuum cleaner delivers tangible benefits for facilities focused on operational efficiency, employee safety, and regulatory compliance. Here are the key advantages:

- Improved Workplace Safety: Immediate removal of hazardous dust, combustible particulates, and liquid spills lowers the risk of accidents, respiratory illnesses, fires, and slip-and-fall incidents.

- Regulatory Compliance: Industrial vacuums help organizations meet OSHA, EPA, NFPA, FDA, and local safety/environmental guidelines related to air quality, hazardous material handling, and industrial hygiene.

- Higher Productivity & Efficiency: Automated debris removal, reduced manual cleaning labor, and less unplanned downtime allow staff to focus on core production tasks and increase throughput.

- Cost Savings: Minimizing equipment wear, preventing production stoppages, supporting material reclamation, and reducing cleaning-related labor all contribute to lower operating costs.

- Enhanced Facility Cleanliness: Consistent cleaning ensures a professional, presentable workplace environment, improves employee morale, and extends the lifespan of expensive equipment and infrastructure.

- Versatility: Industrial vacuums handle a broad spectrum of substances—from fine powders, toxic dust, and combustible materials to bulk debris and liquid spills—across multiple facility zones.

- Customizable & Scalable Solutions: Modular designs, a variety of attachments, and specialized filtration options enable tailored cleaning programs for small workshops or large manufacturing complexes.

- Environmental Responsibility: Efficient dust collection and material reclamation support green manufacturing initiatives and sustainable waste management practices.

Industrial Vacuum Cleaner Buying Guide: What to Consider

Selecting the right industrial vacuum cleaner requires careful evaluation of several key factors, each of which influences cleaning performance, operational costs, and long-term ROI. Consider the following decision criteria to ensure your investment aligns with your facility’s needs:

- Material Type: What substances will you be collecting—dry dust, wet materials, hazardous powders, combustible dust, metal shavings, or bulk debris? The nature of your waste stream determines the required filter type, tank construction, and vacuum power.

- Application Environment: Is your cleaning area classified as hazardous or explosive (triggering ATEX/IECEx requirements), or does it demand high air purity (such as cleanrooms or food processing)?

- Vacuum Power & Airflow: Choose a machine with the appropriate suction strength (measured in inches of water lift) and airflow (measured in cubic feet per minute, or CFM) for your cleaning workload and hose length.

- Filtration Requirements: Does your industry require HEPA, ULPA, activated carbon, or specialty filters for hazardous material containment or odor control? Confirm third-party certification to meet compliance standards.

- Tank Capacity: Larger tanks reduce emptying frequency and are ideal for high-volume debris or continuous duty applications. Consider quick-release or tilt-dump designs for faster turnaround.

- Mobility & Portability: Decide between portable, stationary, wall-mounted, or truck-mounted vacuums, based on your facility’s layout and cleaning zones.

- Durability & Construction: Look for robust materials—such as stainless steel, heavy-gauge plastics, or powder-coated steel—to withstand harsh chemicals, abrasives, or corrosive environments.

- Ease of Maintenance: Systems with tool-free filter access, simple waste disposal, and automatic filter cleaning minimize maintenance labor and reduce downtime.

- Noise Levels: For noise-sensitive areas, check decibel ratings and consider vacuums with sound-dampening insulation or mufflers.

- Energy Efficiency: Some industrial vacuum models offer energy-saving motors, variable speed drives, and programmable shut-down features to lower utility costs and reduce carbon footprint.

- Integration with Existing Systems: Consider whether the vacuum can be integrated with process equipment, central dust collection, or building automation systems.

- Support & Parts Availability: Ensure the manufacturer or distributor offers local service, replacement parts, and technical support for long-term reliability.

Ready to compare top-rated industrial vacuum cleaners? Browse our HEPA vacuum cleaner lineup or request a custom quote tailored to your application.

Frequently Asked Questions About Industrial Vacuum Cleaners

What makes industrial vacuum cleaners different from commercial or household vacuums?

Industrial vacuum cleaners are engineered for heavy continuous use, higher suction power, and the ability to handle hazardous, abrasive, or large-scale debris. Their advanced filtration systems, durable construction, and customizable features set them apart from standard vacuums designed for home or light commercial use. Industrial vacuums are built to withstand harsh conditions, process a wide range of materials, and support compliance with stringent industry regulations.

When should I choose an explosion-proof or ATEX-rated industrial vacuum?

If your facility processes combustible dust, flammable powders, or operates in classified hazardous zones (such as paint shops, grain silos, or chemical plants), an explosion-proof or ATEX-certified vacuum cleaner is essential for safety and regulatory compliance. These models feature grounded components, anti-static hoses, spark-resistant materials, and are rigorously tested for operation in potentially explosive atmospheres.

Can industrial vacuum cleaners be used for both wet and dry materials?

Yes, many modern industrial vacuum cleaners are designed for versatile wet/dry operation, enabling seamless cleanup of both liquid spills and dry debris. Always verify the vacuum’s tank material, filter type, and the manufacturer’s specifications for safe and efficient mixed material handling. Wet/dry vacuums streamline cleaning workflows, especially in facilities with frequent spill risks.

How often should industrial vacuum cleaner filters be replaced?

Filter replacement frequency depends on usage intensity, the type of materials collected, and the specific filtration technology. HEPA and ULPA filters may require more frequent changes in high-dust or hazardous environments to maintain air purity and suction performance. Consult your manufacturer’s guidelines for best practices, and consider vacuums with filter monitoring sensors for predictive maintenance.

What is the average lifespan of an industrial vacuum cleaner?

With proper preventive maintenance, regular filter changes, and adherence to usage guidelines, industrial vacuum cleaners can last 10 years or more. Factors impacting lifespan include usage frequency, the abrasiveness/corrosiveness of collected materials, maintenance routines, and the quality of the vacuum’s construction.

How do I choose the right attachments and accessories for my industrial vacuum?

Attachment selection depends on your cleaning tasks: choose crevice tools for tight spaces, wide floor nozzles for large areas, anti-static hoses for combustible dust, and squeegees for liquid spills. Specialty accessories such as brush heads, extension wands, and HEPA filter upgrades can further enhance cleaning performance in specific applications.

Emerging Trends in Industrial Vacuum Technology

As industries continue to prioritize workplace safety, environmental sustainability, and operational efficiency, industrial vacuum technology is evolving rapidly. Here are some leading trends influencing the future of industrial cleaning equipment:

- Smart Vacuums: Integration of IoT sensors and remote monitoring capabilities for predictive maintenance, usage tracking, filter status alerts, and fleet management—minimizing downtime and optimizing performance.

- Green Technology: Development of energy-efficient motors, recyclable components, and advanced dust containment systems to minimize environmental impact and support sustainable manufacturing practices.

- Automated & Robotic Vacuums: Deployment of autonomous machines for large-scale floor cleaning, hazardous area maintenance, and high-frequency cleaning tasks in warehouses and production plants, reducing labor costs and exposure risks.

- Enhanced Filtration: Introduction of antimicrobial filters, activated carbon odor removal, and improved particle capture to address evolving health and safety standards in healthcare, food, and pharmaceutical industries.

- Modular & Customizable Designs: Flexible systems with interchangeable attachments, modular collection tanks, and scalable suction power for diverse cleaning scenarios and facility expansions.

- Data-Driven Cleaning: Adoption of digital dashboards and analytics for tracking equipment utilization, consumable usage, and compliance reporting.

Industry Use Cases: Real-World Applications

Curious about how industrial vacuum cleaners are used in your sector? Explore these industry-specific applications and discover the role these machines play in optimizing facility operations:

- Food & Beverage: Maintaining allergen-free production zones, cleaning conveyor belts, removing flour dust, sugar, or spice residues, and ensuring compliance with FDA and HACCP hygiene regulations.

- Pharmaceutical Manufacturing: Capturing airborne pharmaceutical powders during blending, granulation, and packaging; preventing cross-contamination and supporting cGMP protocols.

- Automotive Assembly: Extracting welding fumes, collecting metal shavings, cleaning up lubricants and paint overspray for safer, more efficient production environments.

- Aerospace: Removing fine metallic and composite dust during parts manufacturing, cleaning aircraft interiors, and supporting maintenance, repair, and overhaul (MRO) operations.

- Electronics: Cleaning sensitive production equipment, removing soldering debris, and minimizing static electricity risks in semiconductor fabrication or PCB assembly lines.

- Construction & Demolition: Rapid cleanup of silica dust, concrete particles, insulation fibers, and demolition debris to meet OSHA standards and speed up project timelines.

- Public Transit & Transportation: Cleaning bus, train, subway, and airplane interiors; maintaining depots, terminals, and transportation infrastructure.

- Recycling & Waste Management: Sorting and reclaiming valuable materials, reducing landfill waste, and supporting sustainable circular economy goals.

Want to see case studies or testimonials from your specific industry? Request real-world examples showcasing industrial vacuum cleaner performance and ROI in environments similar to yours.

How to Maximize ROI from Your Industrial Vacuum Investment

To maximize the return on investment (ROI) from your industrial vacuum cleaner, implement these best practices for equipment selection, operation, and maintenance:

- Match equipment size and features to your facility’s specific cleaning requirements—avoid over- or under-sizing to optimize performance and cost.

- Train staff on proper vacuum use, filter changes, and routine maintenance procedures to ensure safe, efficient operation.

- Schedule regular preventive maintenance (including filter inspection, hose checks, and motor servicing) to extend machine life and reduce unscheduled downtime.

- Monitor filter status and replace consumables on schedule to maintain peak suction, air quality, and regulatory compliance.

- Use OEM parts, recommended accessories, and manufacturer-approved filters to safeguard warranty coverage and maximize cleaning efficacy.

- Integrate your vacuum system with facility management or building automation platforms for data-driven performance tracking.

- Partner with trusted distributors or service providers for local support, repair, and spare parts availability.

Industrial Vacuum Cleaner Brands and Manufacturers

Choosing the right industrial vacuum cleaner brand ensures access to reliable performance, technical support, and industry-specific solutions. Some of the most respected manufacturers in the industrial vacuum sector include:

- Nilfisk Industrial Vacuums

- Ruwac USA

- American Vacuum Company

- HafcoVac

- National Turbine Corporation

- Tiger-Vac Inc.

- Delfin Industrial Vacuums

- Goodway Technologies

When comparing industrial vacuum brands, consider factors such as warranty terms, technical support, spare parts availability, distributor/service network, equipment customization options, and compatibility with accessories and upgrades. Reading independent reviews and requesting product demonstrations can also help you make an informed decision.

Ready to Choose the Best Industrial Vacuum Cleaner?

Selecting the right industrial vacuum cleaner can transform your facility’s cleaning efficiency, worker safety, and regulatory compliance. Whether your focus is on hazardous dust collection, spill recovery, process-integrated cleaning, or general facility maintenance, there’s a solution tailored to your industry, materials, and budget. For expert guidance, product comparisons, and custom quotes, contact our team today.

Looking for more information or exploring specialized solutions? Check out our comprehensive guides on HEPA filtration systems, explosion-proof industrial vacuums, and central vacuum systems for advanced industrial cleaning applications.

Still Have Questions? Start Your Research Here

Are you comparing industrial vacuum cleaner prices, seeking technical data sheets, or need help with regulatory compliance for combustible dust collection? Our resources and experts are here to assist. Ask an industrial vacuum expert or review our Knowledge Base for more answers to frequently asked questions like:

- What is the best industrial vacuum for silica dust control in construction?

- How do I calculate the required CFM and suction for my application?

- Which vacuum systems are OSHA compliant for lead, asbestos, or hazardous material cleanup?

- What maintenance is required for explosion-proof vacuum cleaners?

- How do central industrial vacuum systems compare to portable units?

Start your industrial vacuum cleaner research today and discover the ideal solution for your facility’s safety, compliance, and cleaning performance goals.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services