Every component in their design is made of non-sparking materials like fiberglass and stainless steel, significantly reducing the risk of static charge or a spark from material impact. Read More…

We are vacuum experts, both for vacuum cleaners and vacuum systems for manufacturing needs. We will create custom systems that will help you reach your industry goals- no matter what they our.

As a leader in the vacuum cleaner manufacturing industry, Multi-Vac offers vacuums for a variety of applications. Products include central industrial vacuums, portable vacuum cleaners and more.

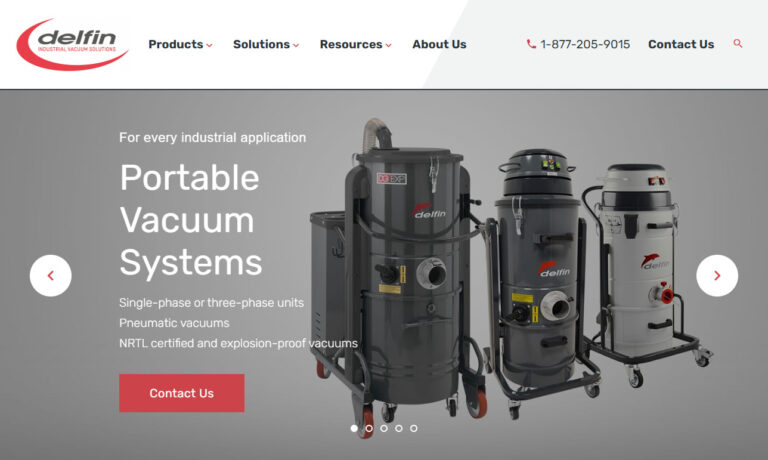

Delfin Industrial Vacuums is an innovative leader in the vacuum cleaners industry. We focus on continually improving our products and our services, so you are only ever getting the best from us. Our team is dedicated to finding the right industrial vacuum system for your company’s specific needs. Delfin is an ISO 9001 certified company. We offer our customers unrivaled customer service and...

At Legends Equipment Company, we take pride in our custom-engineered central vacuum systems designed for heavy-duty industrial applications. Our vacuum cleaners are a testament to our commitment to excellence in providing efficient and powerful solutions for challenging environments. With a focus on innovation and reliability, we understand the unique demands of industrial settings, and our...

We aim to achieve measurable cost savings for you while producing a cleaner and safer work environment in your workplace. We meet your needs for cleaning or maintaining, recycling, non-destructively excavating, or improving air quality.

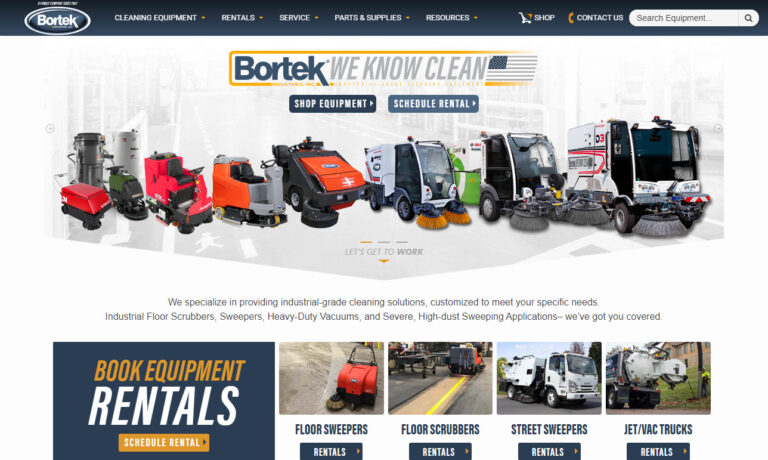

Being a world leader in the industrial vacuum arena defines Bortek. We offer litter vacuums, industrial vacuums and scrubbers, HEPA vacuums, portable vacuums and more. Our vacuum cleaners are used in industrial and commercial applications. Our industrial specialty vacuums are at your service.

Goodway Technologies Corporation specializes in industrial, commercial and wet/dry vacuum cleaners. We provide excellent customer service and support in order to help each customer choose the best industrial vacuum cleaner, vacuum cleaner system or other vacuum product to suit exacting specifications.

More Explosion Proof Vacuum Manufacturers

They are used in construction zones as well as industrial manufacturing environments when cleaning of hazardous materials like flammable liquids, large amounts of fine dust, fibers or filings, aluminum powder, petrochemicals, and debris is necessary.

Explosion proof vacuums are utilized by manufacturers of solid organic materials like sugar, corn starch, wood, or plastic pellets because they risk serious fires if the dust they produce becomes finely divided and dispersed. Polishing, grinding, transporting, and shaping many different materials produces dust and small particles, which become dispersed around facilities and can easily catch fire.

Areas that contain flammable gas or vapor are also subject to extra caution while vacuuming. Ignition of these materials is not uncommon; it can be caused by hot surfaces, electrical sparks, flames or glowing embers, metal-to-metal contact, and static electricity.

Most explosion proof vacuums are powered by compressed air instead of electricity and can handle wet or dry materials. One of the largest causes of vacuum fires is large amounts of fine dust. If the dust is regularly cleaned, the risk of fire goes down but it does not disappear.

Static dissipation, electrical insulation, and chemical neutrality are all important factors in explosion proof vacuum construction.

The housing can be made of reinforced fiberglass or stainless steel, and components like inlets and casters are often made of plastic or bronze. Inside the vacuum, an immersion separator quenches the material with water, eliminating the risk of combustion within the storage tank. There are also filters to reduce airborne dust.

In order to be considered fully explosion proof, vacuums must reach strict US National Electrical Code 500 and 505 standards. Some may claim to be explosion proof, but unless they are certified, using them could be unsafe. There is a rating system of classes, divisions, and groups put forth by the NEC that matches certain hazardous environments and materials with the appropriate vacuum type. All hoses, tools, and attachments must be static conductive, dissipative, and fully grounded so there is no risk of sparking during operation.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services